The Colsman performance.

The right process for every shape.

Forming processes

With our diverse production processes, we can always manufacture components according to customer requirements. Of course, we are available to answer any questions about the right method and will be happy to advise you!

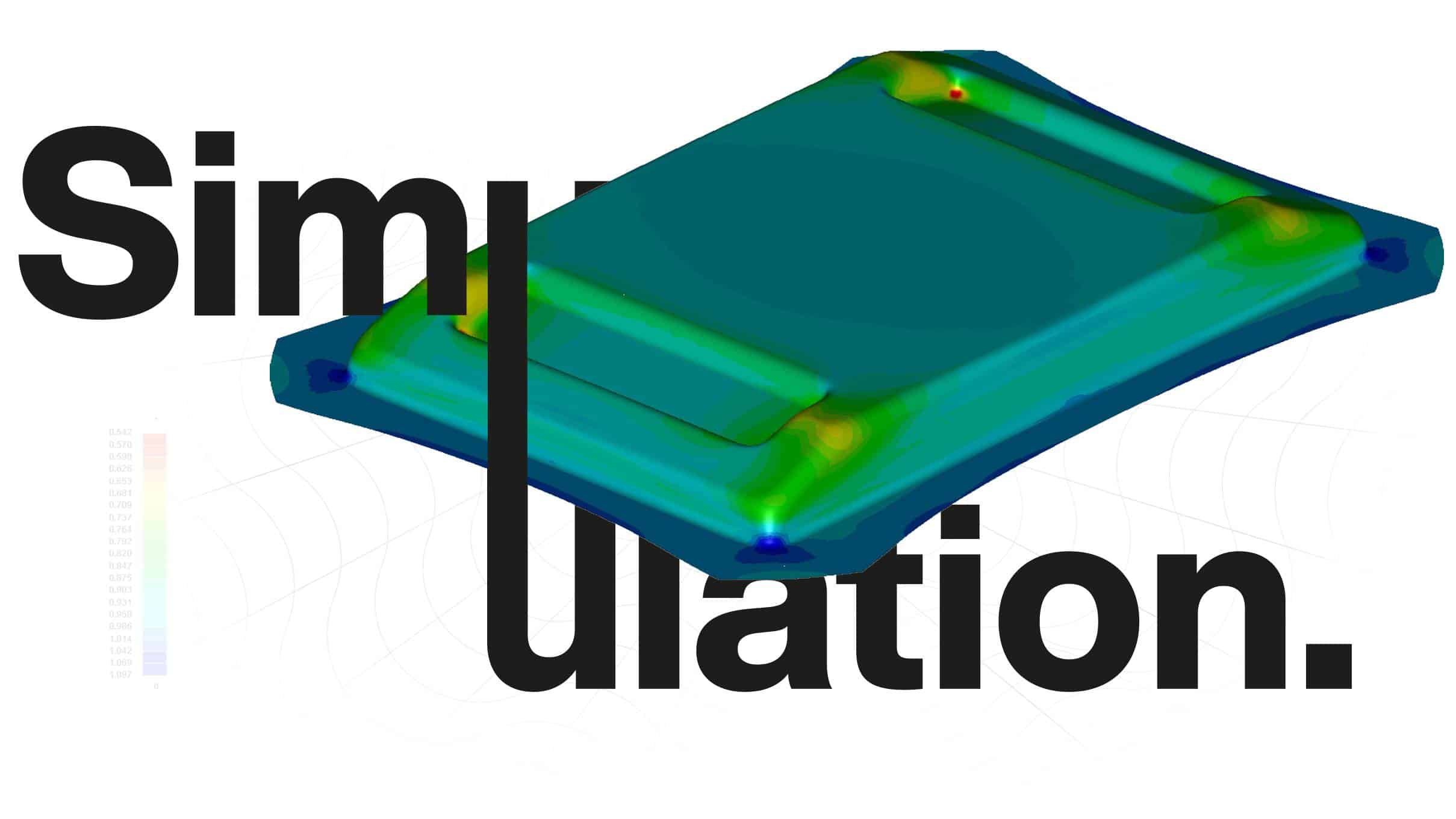

Simul

Colsman supports you as a development partner in perfecting your components. Our FEM simulation program allows us to evaluate the module design of your components in terms of production technology and optimize it if necessary. In this way, we not only guarantee the ideal implementation of your requirements, but also find the most economically viable method for manufacturing your components.

Assembly group

If desired, Colsman can also take over the assembly of entire subassemblies in addition to further processing.

Forming processes

In addition to the actual sheet metal forming, Colsman also offers various processes for the further processing of formed metals.

Punching and cutting

Colsman's finishing capabilities include die cutting, nibbling and lasering.

Machining finishing

Turning and milling are machining processes that Colsman uses for the further processing of metals.

Joining operations

Colsman applies various joining operations for the further processing of metals: Spot and laser welding, MIG, MAG and TIG welding, and gluing.

Surface treatment

The quenching and tempering of metallic surfaces is not only for aesthetic reasons, but also affects the longevity of the formed components.

Hydroforming

The innovation in metal forming. The high-quality process leaves many design options and creates perfect surfaces.

We also perform on the phone.

Enders Colsman INC.

Brauck 1

58791 Werdohl

Phone: +49 (0)2392 / 9782 01

Fax: +49 (0)2392 / 9782 81

Email: info@colsman-forming.com