A process with many advantages.

A really good move.

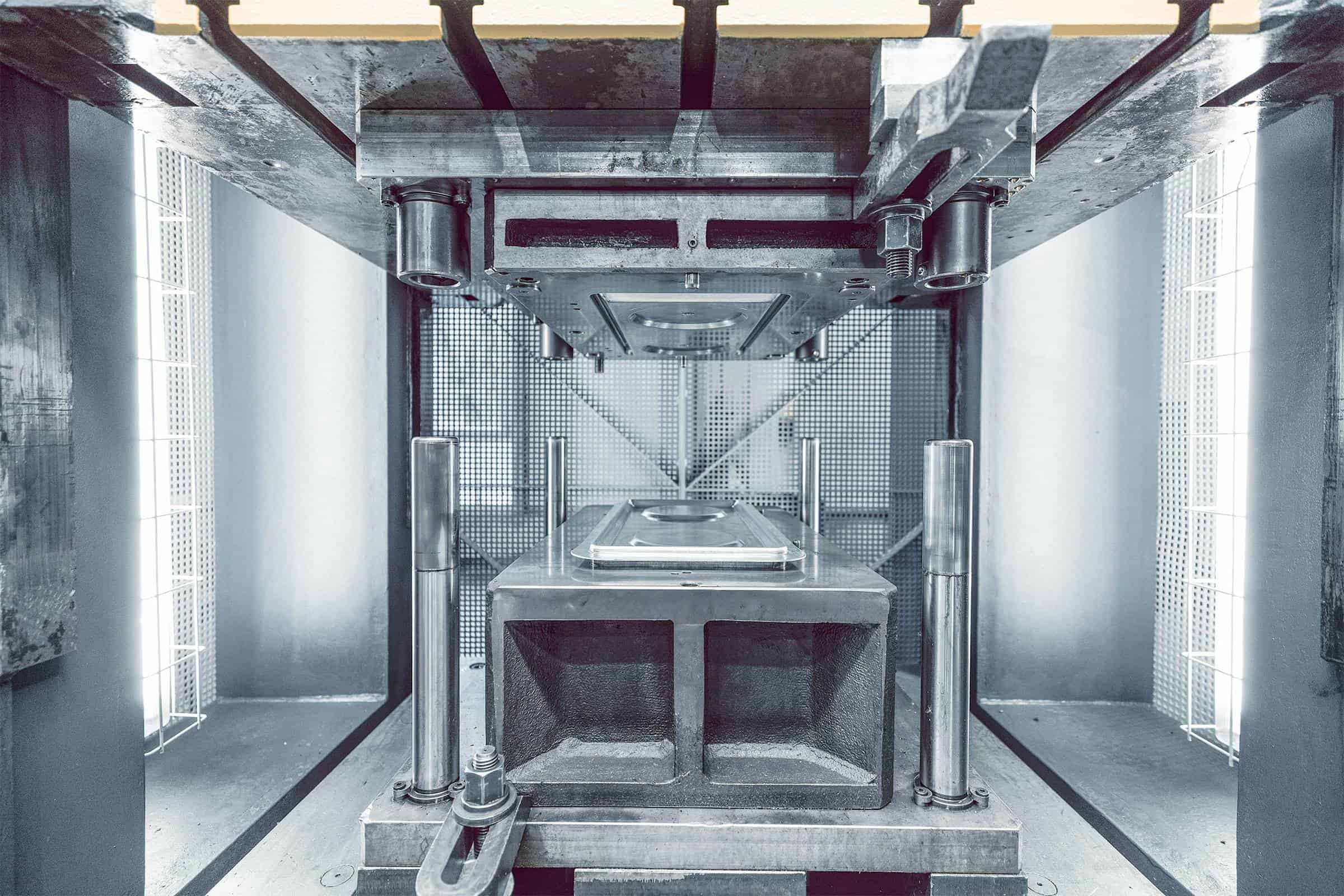

Deep drawing is one of the established processes for metal forming. The process generally uses two dies that are brought together under hydraulic pressure to form flat raw material into a three-dimensional shape. Deep drawing is extremely cost-effective and is mainly used when components with a large, smooth surface are required - such as car parts, household appliances or packaging.

Precision through thick and thin.

Metal forming by deep drawing offers several advantages: It enables the production of components with complex contours and geometries that would be extremely cost-intensive or not even feasible with other processes. With the aid of deep drawing, sheets can be formed into thinner and thicker material thicknesses, which makes a decisive difference depending on the area of application. Another advantage is the high precision and reproducibility of the products, as the tools are manufactured in Colman's in-house tool shop. And deep drawing also proves to be a really good move in terms of economic aspects: the process enables production in large quantities within a very short time.

We also perform on the phone.

Enders Colsman INC.

Brauck 1

58791 Werdohl

Phone: +49 (0)2392 / 9782 01

Fax: +49 (0)2392 / 9782 81

Email: info@colsman-forming.com